5 Structural Adhesives Myths Disproved

There are plenty of misconceptions when it comes to structural adhesives in industrial applications. 3M, a leader in structural adhesive technology, helps dispel 5 common structural adhesive myths.

MYTH #1

Structural Adhesives Don't Hold

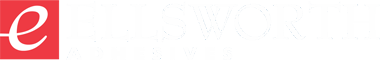

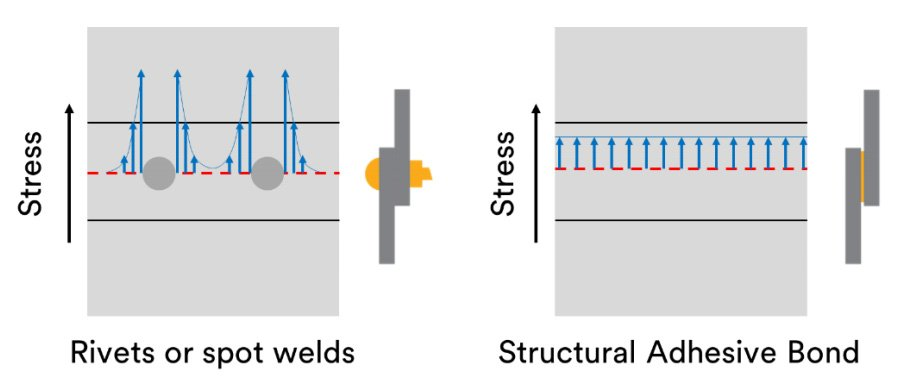

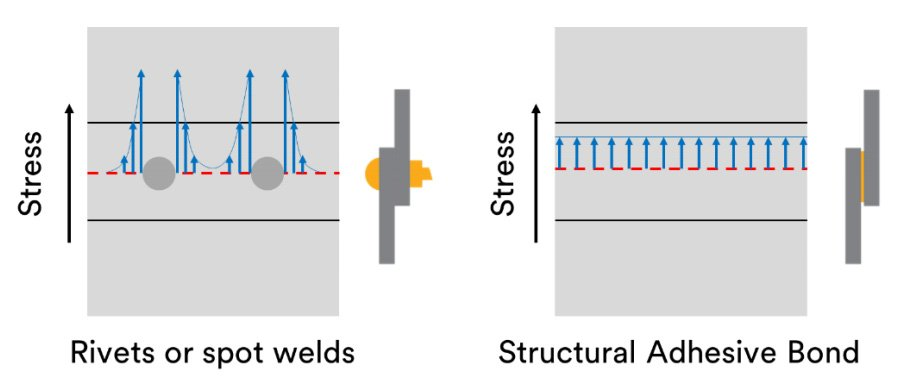

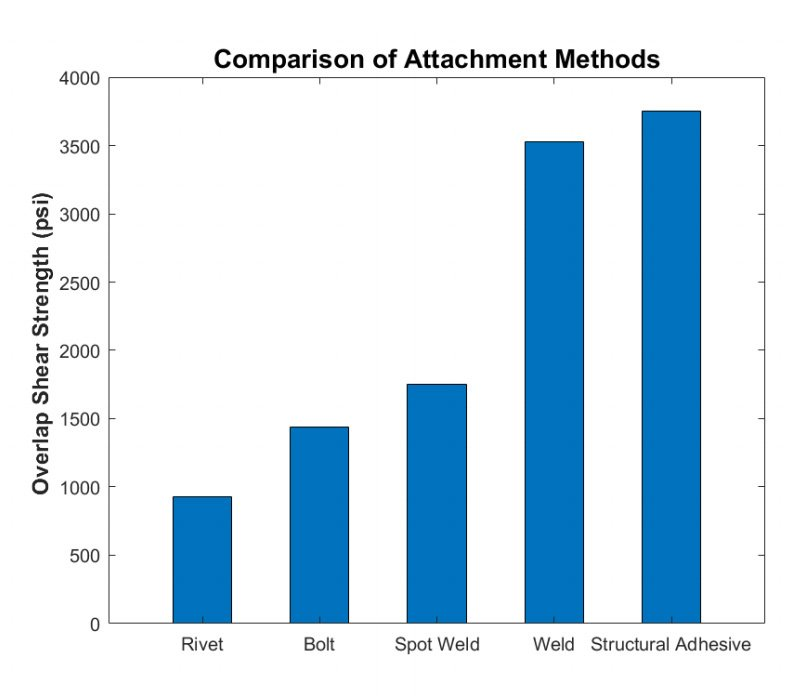

Skepticism that structural adhesives provide strong, durable bonds is a common mistake in joint design. Engineers often rely on traditional joining methods without considering the unique advantages of structural adhesives. Understanding how these materials work – as well as how they compare to screws, rivets, and welds – helps identify valuable performance and cost advantages.

Benefits of Structural Adhesives

Load distribution throughout the bond line

Improved joint strength

Enhanced aesthetics

Similar or higher strength bonds compared to traditional joining methods

Works with applications that can't use screws, rivets, or welds (lightweighting, composite bonding)

Thanks to their high-strength performance that often surpasses traditional screws and rivets, structural adhesives are an ideal choice for even the most demanding applications like aerospace components and carbon fiber drive shafts. Manufacturers often have the additional option of combining structural adhesives with traditional joining methods to enhance durability.

Myth #2

Holding Pieces Together is All That Matters

There is more to bonding and adhesion than just selecting the right product and applying it to your part. It is also important to consider the production and operating conditions of the final product. The most common challenges fall into three categories: production, labor, and design.

Production Challenges

Evaluating your entire production process can help identify process steps where changes could help an adhesive work and perform better. This can also lead to areas where you might reduce time or labor, like the time spent inserting mechanical fasteners or refinishing weld distortions.

Common challenges include:

- 1. Need to shorten overall cycle time

- 2. Concerns of high scrap or rework rates

- 3. High levels of work in process (WIP)

- 4. Moving to a more automated process to address a shortage of skilled labor

Labor Challenges

Labor is an important part of the production process, with structural adhesives offering a variety of benefits.

Common challenges include:

- 1. High turnover creates demand for standard operating procedures (SOPs) and optimizing processes for consistency

- 2. Process training

- 3. Worker fatigue and injuries

Design Challenges

Factors like appearance, weight, cost, and material type play a role in making the right bonding choice.

Common challenges include:

- 1. Pressure to reduce cost or weight

- 2. Need to create more streamlined designs by removing metal attachments

- 3. Using new difficult-to-bond materials such as LSE plastics

- 4. Assemblies that need to reduce noise and vibration or withstand harsh conditions

- 5. Issues with bond line read-through that occur while using your current adhesive

- 6. Changing or challenging conditions of final end-use of the assembly

MYTH #3

"I've Tried One So I've Tried Them All"

After a failed attempt to use a structural adhesive, it is important to investigate why the previous option failed to meet all expectations. This understanding provides insight into the attributes that are needed in subsequent adhesive selection.

An assembly created with structural adhesives can fail to meet expectations for several reasons. These reasons can be process-dependent, end use-dependent, or a combination of the two.

|

PROCESS DEPENDENT

|

- Surface preparation: cleanliness, surface energy modification, etc.

- Dispensability: viscosity, sag behavior, etc.

- Curing times: open time, time to handling strength, time to full cure.

|

|

END OF USE DEPENDENT

|

- Mechanical properties: modulus, elongation, etc.

- Adhesion strength to chosen adherends in various stress modes: shear, tensile, impact, etc.

- Environmental resistance: temperature and humidity extremes, solvents or fluids, etc.

|

Once the failure analysis is complete, it is important to investigate other adhesives that have the newly discovered and required attributes.

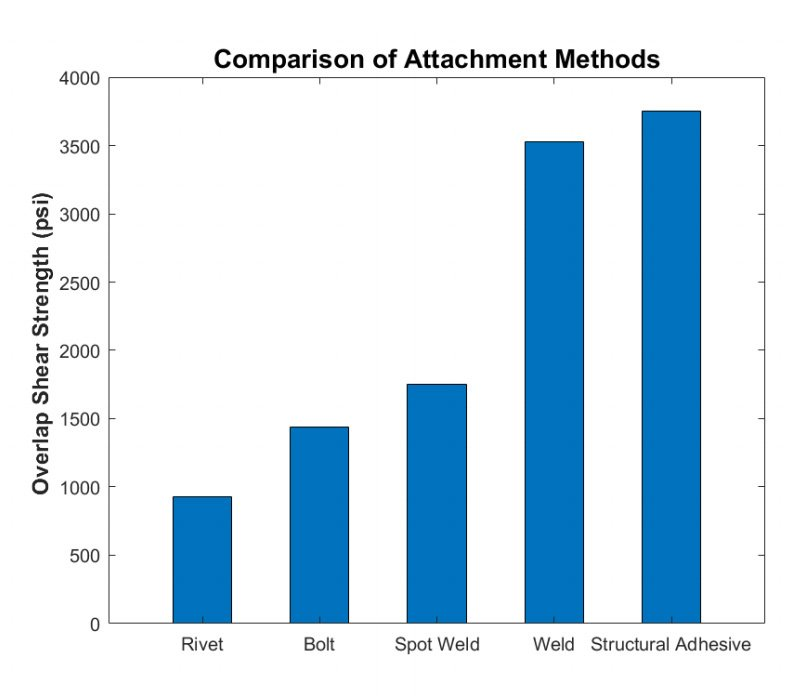

The 3M structural adhesive portfolio includes three chemistry families: acrylic-based, epoxy-based and polyurethane-based. Choosing the right chemistry will depend on your application, as well as the material’s processing and physical characteristics.

Processing Characteristics to Consider

- Shelf life: How long a product can remain viable at a production facility and how frequently the adhesive would need to be ordered

- Rate of Strength Build: How fast an adhesive will build strength after a bond has been made

- Minimal Surface Preparation Required: How much time/prep is associated with the assembly process

Physical Characteristics to Consider

- Shear Strength: Adhesives perform best and provide the highest strengths when stressed in shear mode and on properly prepared adherends

- Peel Strength: A good indicator and proxy for how much energy an adhesive can absorb before failure

- Environmental Resistance: Higher environmental resistance ratings indicate the best chance of surviving the exposure while retaining the original strength of the joint

MYTH #4

All Structural Adhesives Are Epoxies

Structural adhesives are commonly classified according to their base chemistry, with epoxy being the most-recognized term. However, it is not the only material that can provide structural strength to assemblies. Other common structural adhesive families include acrylics, one and two component urethanes, cyanoacrylates, and anaerobic adhesives. Understanding the capabilities of these adhesives gives you freedom and flexibility to choose the best adhesive to suit individual bonding applications.

Types of 3M Structural Adhesives

|

ADHESIVE

|

KEY STRENGTH

|

USES

|

|

Epoxy

|

High bond strength & durability

|

- Applications with harsh environments

- Sporting goods

- Renewable energy applications

|

|

Acrylic

|

Robustness & fast curing

|

- Panel-to-frame bonding

- Enclosures

- LSE plastics

|

|

Urethane

|

Flexible & strong

|

- Composite panel bonding

- Glass bonding

- Flexible potting applications

|

|

PUR

|

Fast holding power with flexibility

|

- Panel & stiffener bonding

- Woodworking

- Electronics

- Glass + plastic bonding

|

|

Instant

|

Speed

|

- Plastic + metal assembly

- Rubbers + elastomers

- Decorative wood trims

|

|

Anaerobic

|

Keeps nuts & bolts from loosening

|

- Threadlocking

- Thread sealing

- Gasketing

|

MYTH #5

"I'm On My Own to Figure This Out"

Just as design engineers are experts on the products they are creating, there are bonding experts who can help you select the right adhesives to make it possible.

Ellsworth Adhesives partners with the 3M global engineering and development team of experts in material and adhesive science who regularly work with multiple bonding product options. Our team of Glue Doctors® are well-versed in 3M products and technology, with access to a host of valuable resources. With our help, you can be confident that you’ll making the right structural bonding adhesive decision.

|