Understanding adhesion is essential for many industrial and electronic applications where materials need to be bonded together. The strength and reliability of an adhesive bond can impact the performance, durability, and safety of a product.

This guide covers the basics of adhesion, surface preparation, adhesive types, and environmental factors.

1. How Adhesion Works

Adhesion occurs when an adhesive form a bond between two surfaces. Several factors influence how strong this bond will be:

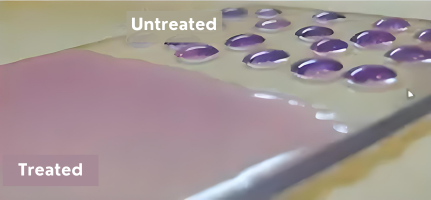

· Surface Energy: Materials with high surface energy (like metals) allow adhesives to spread evenly, leading to stronger bonds. Low surface energy materials (like engineering plastics) may require special adhesives or surface treatments to improve bonding.

· Mechanical Interlocking: Adhesives can flow into tiny pores or rough areas on the surface, creating a physical "lock." Roughening surfaces through sanding or etching enhances this process.

· Chemical Bonding: Adhesives may form strong chemical bonds with the surface. Depending on the adhesive, this bonding could involve covalent, ionic, or hydrogen bonds, which add durability to the bond.

· Wetting: For good adhesion, the adhesive must wet the surface properly. Wetting ensures that the adhesive spreads across the material, maximizing the bond strength.

2. Surface Preparation

Proper surface preparation is key to achieving a strong bond:

· Cleaning: Dirt, oil, and contaminants on surfaces can interfere with adhesion. Always clean surfaces before applying adhesive to ensure a solid bond.

· Roughening: For smooth surfaces, roughening them by sanding or etching can provide the adhesive with more surface area to grip.

· Primers: Some materials may need a primer to help the adhesive bond better. Primers act as a bridge between the surface and the adhesive, improving adhesion.

3. Choosing the Right Adhesive

Selecting the correct adhesive for the materials you are bonding is crucial for creating a strong, lasting bond. Here’s a quick guide:

· Epoxy: Strong and durable, ideal for bonding metals, plastics, and ceramics. Often used in heavy-duty and industrial applications.

· Super Glue (Cyanoacrylate): Fast-curing adhesive for small items and repairs, best for plastics, metals, and ceramics.

· Hot Melt Adhesives: Quick setting, Versatile bonding from packaging to automotive components, No solvents, Temperature-sensitive.

· Silicone Adhesive: Flexible and water-resistant, commonly used as adhesives and sealants in applications that need good environmental performance

· Anaerobic Glue: Cures in the absence of air, typically used for bonding and sealing metal parts in mechanical and automotive applications, like thread lockers

· UV Curing Adhesive: Quick curing when exposed to UV light. Used for precise applications in electronics, glass, and medical devices.

· Adhesive Tapes: Available in various strengths, tapes are ideal for lightweight or temporary bonding. Industrial tapes can also be used for mounting heavier components.

4. Curing Process

Curing refers to the process of the adhesive hardening to create the final bond. The time and conditions for curing vary:

· Fast-Curing Adhesives (e.g., cyanoacrylates, uv curing adhesive): Bonds in seconds or minutes but may not be as strong for heavy or flexible surfaces.

· Slow-Curing Adhesives (e.g., epoxy): Takes several hours or days to fully harden, providing a more durable bond.

Make sure to follow the manufacturer’s instructions for proper curing to ensure optimal bond strength.

5. Environmental Factors

The environment where the adhesive is applied and used plays a role in bond performance:

· Temperature: High temperatures can weaken certain adhesives, while low temperatures can make them brittle.

· Moisture/Humidity: Some adhesives do not bond well in damp conditions. Use water-resistant adhesives, such as silicone, for humid environments.

· Chemical Exposure: Certain chemicals can degrade adhesive bonds over time. Ensure the adhesive is compatible with the environmental conditions it will be exposed to.

6. Testing the Bond

To verify the quality of an adhesive bond, it’s important to test its strength:

· Shear Strength Test: Measures how much force the bond can handle when materials are pulled apart sideways.

· Peel Test: Assesses how easily one surface can peel off the other, important for tapes and labels.

· Impact Test: Tests how well the bond holds under sudden force or shock, critical for applications where impacts are likely.

7. Storage and Safety

Adhesives should be stored properly to maintain their effectiveness, and safety precautions should be followed during use:

· Storage: Keep adhesives in a cool, dry place and check expiration dates to avoid using weakened products.

· Ventilation and Protective Gear: Use adhesives in well-ventilated areas and wear protective gloves and masks as needed, especially when handling industrial adhesives with strong fumes.

Key Takeaways for Good Adhesion

· Prepare surfaces thoroughly by cleaning and roughening them for better bonding.

· Choose the right adhesive for the material and application, ensuring it’s compatible with your working environment.

· Allow proper curing time for the adhesive to fully harden and achieve maximum bond strength.

· Test the bond for durability, especially in critical applications, and consider environmental conditions that could affect performance.

By following these basic adhesion principles, you can ensure strong, reliable bonds across a variety of materials and applications. For expert guidance and tailored solutions that take your projects to the next level, consult with the Adhesives Experts at Ellsworth Adhesives – we’re here to help your work process run smoothly and efficiently!

.png)